Brasserie de Silly is entering a new era with the acquisition of a cutting-edge, fully automated brewhouse from TMCI Padovan (Omnia Technologies), a leader in Italian and European brewing engineering.

With a brewing capacity of 70 hectoliters per batch—that’s 7,000 liters of beer per cycle—this major investment of 3 million euros marks a crucial milestone in our family brewery’s history.

While our current brewhouse has served us faithfully for 35 years and remains in use, this upgrade allows us to merge tradition with innovation.

This new system, entirely built in Europe and already proven in breweries in France, Belgium, and Italy, reflects our commitment to ecological standards, while reducing maintenance costs and increasing productivity.

Beyond efficiency, this investment will elevate the quality of our beers, thanks to precise automation that lets our brewers focus fully on their craft and on quality control.

Included in this upgrade:

- High-performance malt mill

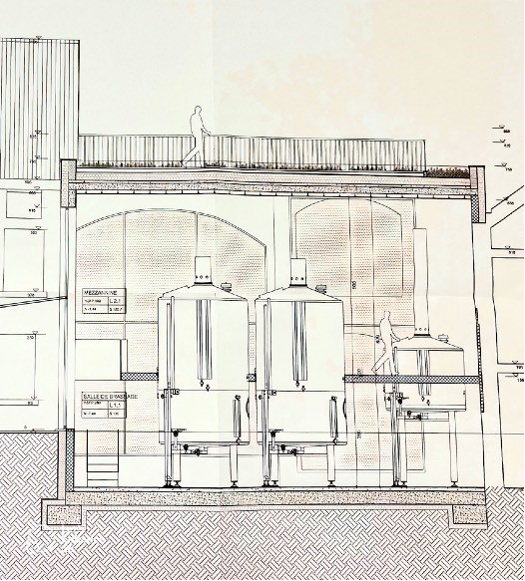

- Mashing, lautering, and boiling vessels

- Next-generation whirlpool

- Plate heat exchanger with energy recovery for sustainable brewing

- Six new fermentation tanks, adding to our existing twenty, significantly increasing production capacity

Optimized Brewing Process

The process begins with malt crushing in the new mill—an essential step to expose starches for enzymatic conversion during mashing. In the mash tun, the crushed malt is combined with hot water to convert starches into fermentable sugars.

The resulting mash is transferred to the lauter tun, where sweet wort is separated from the spent grain. It then enters the boiling kettle, where hops are added at various stages to deliver bitterness, flavor, and aroma.

After boiling, the wort enters the whirlpool to remove solids, then goes through the plate heat exchanger for rapid cooling—preparing it for yeast pitching at optimal temperature.

Fermentation takes place in our 26 tanks (20 existing + 6 new), allowing greater capacity and improved flexibility across beer styles.

Enhanced Quality Control

The new installation enables full automation, freeing up time for our brewers to focus on quality control.

Physicochemical analysis includes:

- pH measurement at key stages (mashing, boiling, fermentation, final beer)

- Gravity monitoring for sugar conversion and ABV determination

- Tests for color, bitterness (IBU), residual sugars, turbidity, and dissolved oxygen

Microbiological analysis ensures healthy fermentation and prevents contamination:

- Microorganism counts and identification of spoilage bacteria (lactic, acetic) and wild yeasts

- Yeast culture purity checks and microscopy

- ATP testing for equipment hygiene

Yield analysis evaluates extraction efficiency from malt—an economic factor—and overall brewhouse efficiency, accounting for losses at each stage.

Finished product quality is verified again through physicochemical and sensory analysis, identifying aromas, flavors, and any defects. Stability tests and gas analysis (CO₂, O₂) ensure proper carbonation and shelf life.

A Sustainable Commitment

In line with our sustainability goals, the investment also includes:

- A new boiler

- Installation of 200 additional solar panels, adding to the existing 400

- An upgraded electrical substation

These efforts aim to reduce our carbon footprint and promote more environmentally friendly brewing practices.

With this new brewhouse, Brasserie de Silly reaffirms its dedication to innovation, quality, and tradition—while looking boldly toward the future.

Project Manager: Bertrand Van der Haegen

Architect: Jean Michel De Haan

Technical Advisor: John Christian Kavakure

External Partners: Daniel Noppe, Didier Franquet

Brewhouse: TMCI Padovan